+421 915 292 412

blahova@victorytech.sk

blahova@victorytech.sk

Drobného 1903/16

841 01 Bratislava-Dúbravka, SlovakiaPo - Pi 8.00 - 17.00

So - Ne ZATVORENÉ

+421 915 292 412

blahova@victorytech.sk

blahova@victorytech.sk

Drobného 1903/16

841 01 Bratislava-Dúbravka, SlovakiaPo - Pi 8.00 - 17.00

So - Ne ZATVORENÉ

VICTORYTECH > WE PROVIDE

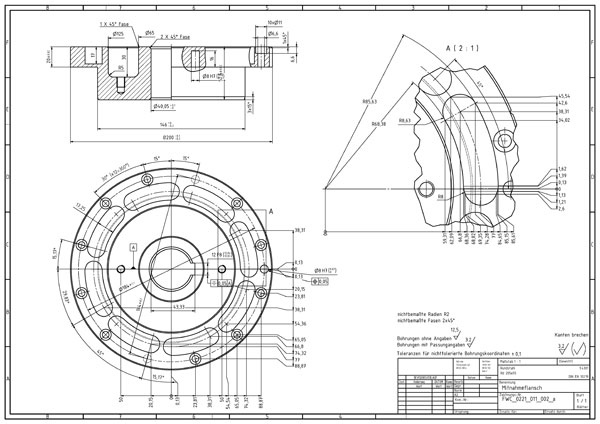

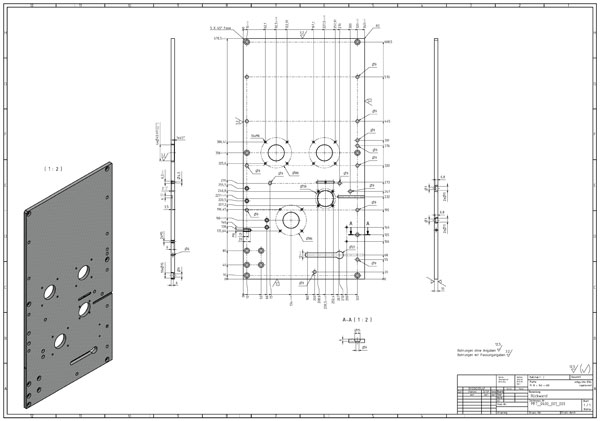

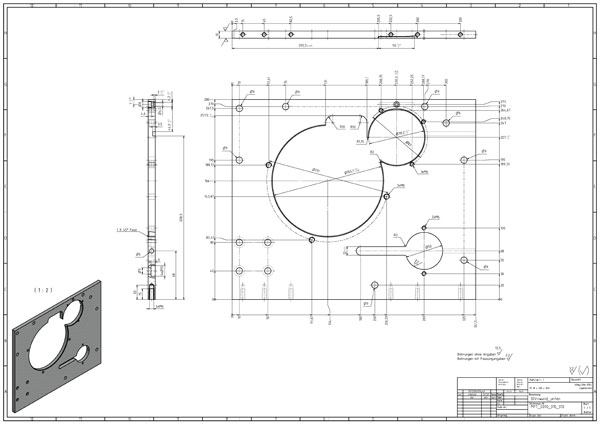

Mechanical engineering production

using documentation provided by the customer:

- short run production and single - part production by conventional machining and CNC machining used for assembly lines and for assembly of special purpose machinery, samples and prototypes production,

- manufacturing of precise parts, tool work on NC and CNC machines (distance rings and flanges of larger sizes, drums and cylinders for conveyor systems)

- production of machine parts, machinery and jigs

- mass production on single spindle and multi-spindle machines, CNC automatic lathes, curve and long turning automatic machines (screws, special bright washers and casings, drilling tools)

- precise mechanics (precise clamps)

- complex machining of products and the subsequent assembly of sophisticated machinery, dimensionally from small parts to weldments and workpieces weighing up to 5,000 kg.

- výroba, opracovanie i mechanická, elektrotechnická, pneumatická a hydraulická montáž sa prevádza modernou technikou.

- manufacturing, machining as well as mechanical, electrical, pneumatic and hydraulic assembly is done with modern technology.

Providing requested quality

of parts and supervision on quality of produced components

- cooperation with contractual partners and holders of quality certificate ISO 9001 with the newest machining technics while we look into the future

- entry isnpection is provided by certified measuring equipment checked and calibrated on regular basis

- measuring of precise parts by modern eqipment 3D CNC Mitutoyo

- if requested we provide measuring protocol along with produced parts

Specialized activities

offered within complex production

- heat treatment – hardening, cementing, tempering, annealing, nitriding

- coating – chrome plating, blackening, sandblasting, galvanizing, painting, nickel plating

- annealing and plazma cutting

- gas and arc welding (CO2, argon)